About Us

Cove Infra Solutions FZCO is a vibrant trading company headquartered in Dubai, United Arab Emirates, operating within the legal framework of the country. With its registered office located in the prestigious Dubai Silicon Oasis, DSO-IFZA IFZA Properties, Cove specialises in the import and export of machinery and materials, focusing on the fields of construction and engineering design. The company takes pride in being a 100% import and export entity, offering innovative solutions and services to elevate infrastructure projects with the major and minor municipalities of the country.

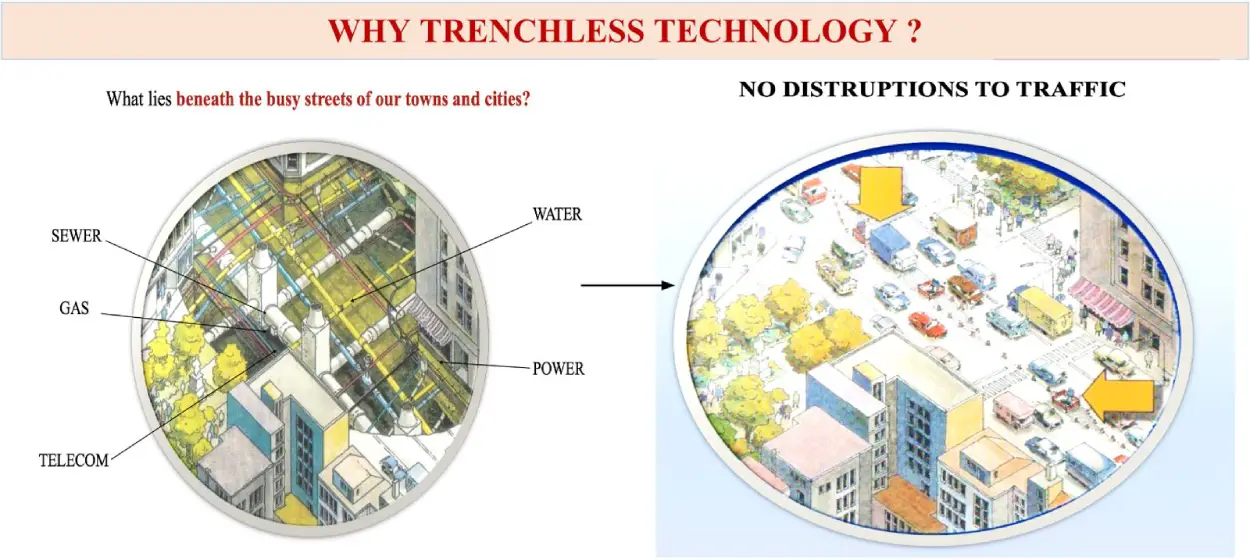

Cove has forged a strategic partnership with Sekisui Singapore Pte Ltd (SSP), an exclusive distributor known for supplying materials dedicated to the rehabilitation of sewerage lines through trenchless technology, including robotic van machines. This collaboration is marked by a comprehensive agreement outlining shared goals and responsibilities between Cove and SSP.

Cove's primary mission is to market and promote SSP's flagship product, SPR™ST, in India, with a particular focus on expanding the application of SSP's trenchless technology in sewerage line rehabilitation projects. The company is keen on contributing to the advancement of construction and engineering practices in the region, collaborating with various infrastructure projects under the government of India.

The collaboration between Cove and SSP is designed to empower Cove in effectively promoting SSP's products in the targeted market. Cove aims to enhance its contribution to infrastructure development to various major and minor municipalities by leveraging SSP's cutting-edge technology and materials.

As part of the collaboration, Cove proposes to finance the supply of materials to designated installers in India, ensuring seamless and efficient execution of sewerage line rehabilitation projects.

Technology and Process

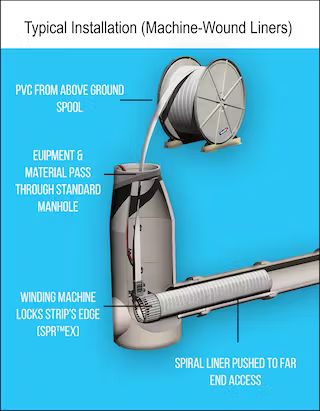

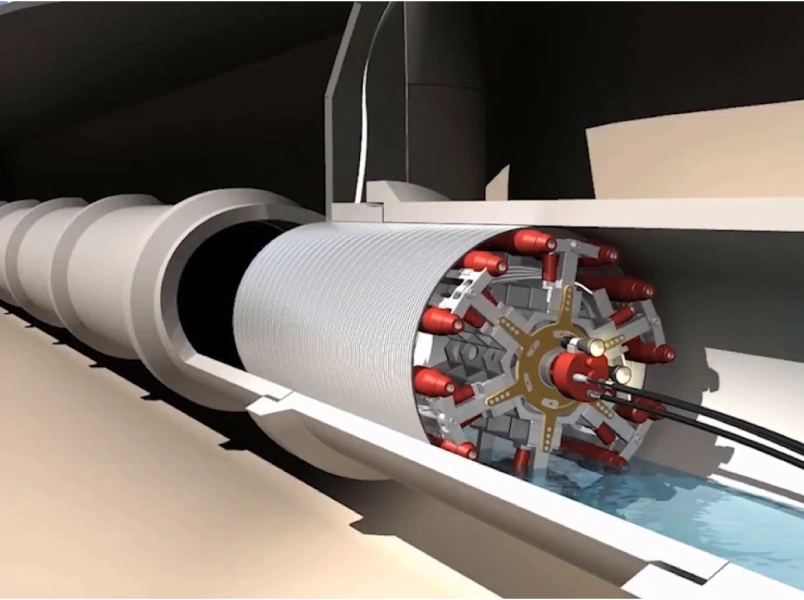

Spiral Wound Liner SPR™ST Machine Wound Spiral Lining (Dia 600 to 3000mm) 100% Trenchless

Rehabilitation Technology: Utilizes trenchless technology to address pipeline issues without excavation.

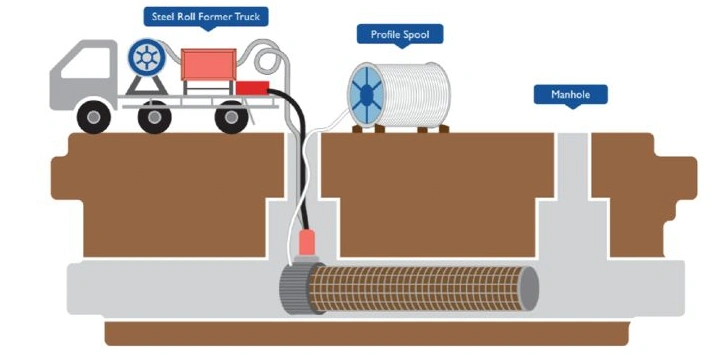

Machine Wound Spiral Lining

Involves winding an extruded plastic profile into a liner, providing high ring stiffness and low weight.

- The system consists of a single manageable PVC or HDPE strip which is spirally wound into the host pipe by a winding machine positioned in the base of a manhole.

- The edges of the strips are interlocked as it is spirally wound to form a continuous watertight liner pipe within the host sewer pipe.

- The PVC or HDPE strip can be also reinforced depending on the structural and design requirements of the sewer pipe.

- Applicable for large diameters and unique-shaped pipelines without the need for excavation or flow interruption, reducing the need for bypass pumping.

| Component | Appellation | Material |

|---|---|---|

| Surface Material | Metal part | Filler (Grout) |

| SPR Profile | Steel Re-Inforcer | SPR Mortar |

| Rigid PVC/PE | Galvanized Steel | Resin Mortar |

Our Product

Spiral Wound Liner SPR™ST Machine Wound Spiral Lining (Dia 600 to 3000mm) 100% Trenchless

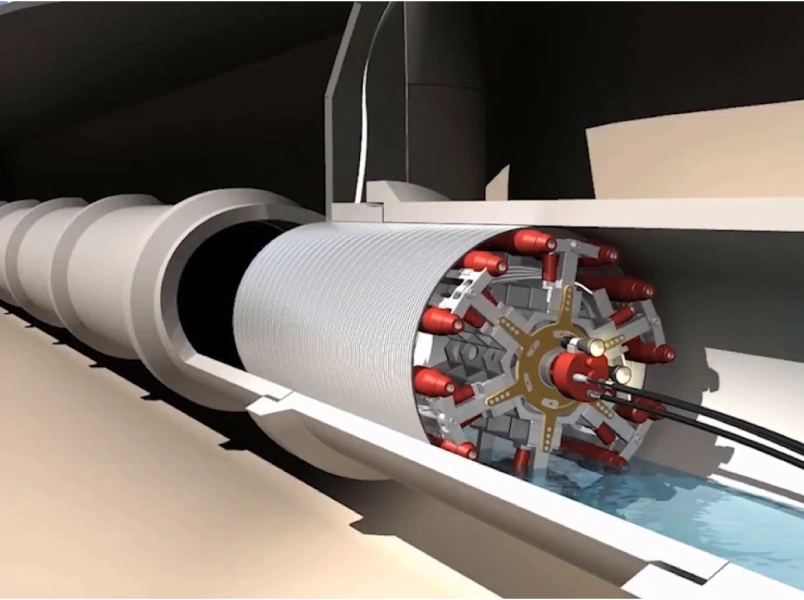

SPR™ST is a machine-wound spiral lining technology designed for the rehabilitation of aging sewers, storm drains, and culverts.

Suitable for structurally rehabilitating various pipelines, including brick, concrete,

glass-reinforced plastic, or corrugated metal. Certification: WRc Approved™ (PT/304/0710).

The SPRTM ST pipe rehabilitation process is a solution for restoring the hydraulic efficiency, reliability and integrity of aging sewers, storm drains and culverts. Where required for greater stiffness, the liner can be reinforced by simultaneously winding a profiled strip of steel under the tees of the PVC profile.

SPRTM ST liners can structurally rehabilitate brick, concrete, glass reinforced plastic or corrugated metal sanitary and storm water pipelines with diameters from 600 mm to over 2500 mm.

A winding machine should be placed in the insertion pit and oriented so that the liner pipe can be spirally wound and inserted (rotated and pushed) directly into the existing pipeline. A reel of extruded PVC profile strip should be positioned near the insertion point. The initial winding process begins with the profile strip being fed into the winding machine, forming the profile strip into the required spiral wound liner pipe diameter, which is simultaneously rotated and pushed along the existing pipeline for its full length to the termination point.

| Profile | Nominal Height | Typical Pipe Diameter | Typical Steel Gauges |

|---|---|---|---|

| 126-20RS | 20 | 150-200 mm | 0.7,0.9,1.2 |

| 91-25RS | 25 | 200-300 mm | 0.7,0.9,1.2,1.5 |

Performance characteristics of Machine Wound Spiral Liner

| Structural Integrity | Materials | Enhanced flow capacity | Affordability | Installation know how | Track Record | Usages sizes |

|---|---|---|---|---|---|---|

| MWSL liner can be designed as structural liners to restores structural integrity of the sewer pipe. The product has been in service for about over 15 years and it can have a life span of 50 years. | The liner material is predominantly uPVC and the ribbed strips are made in factory-controlled quality environment. No wet parts are involved during installation and the installation process is fully mechanized. Cement grouting is required to fill the annulus. For larger diameter sewer rehabilitation, stainless steel stiffening ribs are added to enhance the stiffness capacity of the pipe to meet the required structural capacity of the sewer. | It can be also designed to provide least cross-sectional area reduction. It has water tight mechanical spiral joint along the product pipe and the tests have shown the joint to be water tight. However, no long-term performance testing on the joint exists. The liner material, uPVC, offers least flow resistance | The product cost is relatively low when used without stainless stiffener ribs and grouting. However, the overall rehabilitation cost taking into account of other work elements involved in sewer rehabilitation and the cost of stainless stiffener, the cost is likely to be comparable to other structural liner systems. | The know how is highly specialized and through the work performed in Delhi in the past, installation know how is available to a contractor. | Spiral wound liners have been used in overseas, mainly for smaller diameter rehabilitation. In the recent years spiral wound system has been also used for rehabilitation of larger diameter pipe. In recent DJB projects, the system has been used for rehabilitating non man entry size sewers. | Used as structural liners for non-man and man entry size sewer. |

Our Vision

Cove infra solutions envisions itself as a globally recognized and respected conglomerate known for its commitment to excellence, innovation, and sustainable business practices. His vision encompasses

Global Leadership

Aspires to lead Cove Infra Solutions to the forefront of the global market, setting industry standards and becoming a symbol of quality and reliability.

Innovation and Creativity

A commitment to fostering a culture of innovation and creativity within the group, ensuring the continuous development of cutting-edge products and services across all business verticals.

Sustainability

A vision for Cove Infra Solutions FZCO to be a responsible corporate citizen, incorporating sustainable practices that contribute positively to the environment and the communities in which the group operates.

Customer-Centric Approach

A dedication to understanding and exceeding customer expectations, striving for unparalleled customer satisfaction across all products and services offered by the group.

Diversification and Growth

A strategic approach to diversification, expanding the group's portfolio while maintaining a focus on sustainable and profitable growth in existing and new markets.

Our Mission

Cove infra solutions, through his leadership, is on a mission to.

Quality Excellence

Uphold and enhance the reputation of Cove Infra Solutions FZCO as a symbol of quality excellence in every product and service offered.

Global Expansion

Actively pursue and facilitate the global expansion of Cove Infra Solutions FZCO, strategically entering new markets while strengthening the group's presence in existing ones.

Sustainable Practices

Integrate sustainable and environmentally conscious practices across all business operations, ensuring responsible corporate citizenship and contributing positively to the communities served.

Customer Satisfaction

Prioritize customer satisfaction by consistently delivering products and services that meet or exceed customer expectations, building lasting relationships and loyalty.

Social Responsibility

Fulfill the group's social responsibility by actively engaging in initiatives that contribute to the welfare and development of the communities in which Cove Infra Solutions FZCO operates.

Contact Us

Let’s work together on your next project

Get in touch

Location:

IFZA Property FZCO, Dubai Silicon Oasis, DDP, Building A1, Dubai, United Arab Emirates.